A number of retailers have recently touted success stories around using radio frequency identification, or RFID, for inventory management. The technology offers a number of advantages compared to the humble barcode – but the business case in the warehouse is less clear-cut than it might seem.

An RFID is a chip containing information which can be read through electromagnetic waves. There are passive tags, which require a signal from a reader to be read, and active tags, which have a battery and emit their own signal.

RFIDs are a potential replacement for barcodes, which are widely used for inventory management. Proponents of RFID will cite the accuracy and convenience benefits of the technology, and the added sales benefits coming from the improved visibility of stock.

Unlike barcodes, RFID tags can be read in bulk and at a distance by a reader, with each item having a unique identifier. This means that when an assignment of goods arrives in a warehouse staff can quickly create an accurate picture of inventory without the need for stock-taking every item. 30 individual items can be scanned simultaneously rather than individually.

The sticking point is the cost, however, with Stuart Higgins, former head of logistics at Halfords partner at technology consultancy Bearingpoint noting that even passive RFIDs are expensive at 5 cents per piece. This compares to a fraction of the cost for barcodes. RFIDs can also struggle with interference when being read.

“If you look at RFID in terms of inventory management, tracking and tracing products, it’s quite an expensive way of doing it.

“For most retailers it becomes difficult to justify RFID purely on the grounds of it being a tool to locate stock accurately.”

Where the business case is more reasonable is in the store. Tom Vieweger, business development at RFID consultancy and technology firm Nedap, says that RFID projects start with retail “because there is the place that you earn money.

“A major problem for retailers is poor stock accuracy and visibility. Retailers start with stock accuracy of 60-70% with high theft and low process compliance and existing bookings are error-prone.”

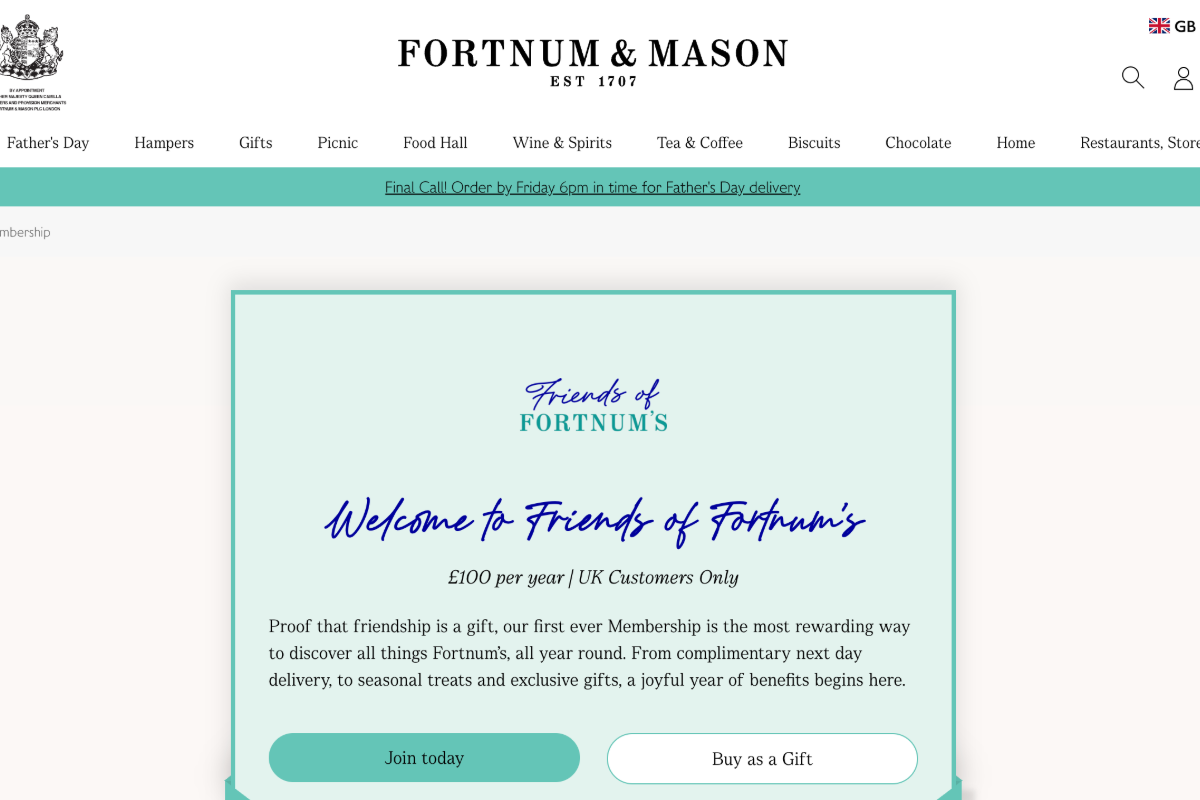

Nedap has worked with River Island since 2017 and with Superdry since 2018 on major RFID roll-outs. Using Nedap’s RFID management software !D Cloud, River Island reports a stock accuracy of over 97%. The bottom line is higher sales and the ability to launch omnichannel services such as ship-from-store, buy online return in store and click and collect.

Both projects begun in stores before moving to warehouses later.

While Vieweger says RFID has a lot to offer in the back end, “the business case needs to come from retail stores; everything you do with logistics is an add-on.”

Higgins at Bearingpoint says that most retailers who are looking at RFID view it as a way of enabling value-adding services in stores.

“It is increasingly possible to integrate digital into the customer journey. We are working with clients now where the customer can pick up a product on the shelf then a scanner can automatically scan it and provide details to the customer.

“You might be buying a garment and then see accessories on a screen. You could stand in front of a mirror and see the garment superimposed on you because the RFID allows the product to be identified.

It is not just customer experiences but also retailer insights. Sabesan Sithamparanathan, CEO of PervasID, says the technology can provide valuable data on how items are interacted within the store:

“For example, which products are repeatedly picked up and moved into another zone but not purchased, which items are taken to the changing room but left there, as well as how long each individual item has been on the shelf. Popular items can be placed in a prime position and items that are often purchased together can be co-located to enhance upselling.”

For the time being, RFID roll-outs are being driven by the store. This could change if the technology becomes significantly cheaper, which barring a significant technological leap is unlikely. It could also change if a highly compelling new use case emerges in the warehouse which can absorb the high costs.

Image credit: Nedap/River Island