Chris Greenwood, CIO, Mamas & Papas spoke to Emma Herrod about how the implementation of carrier management and checkout delivery choice systems have impacted customer experience.

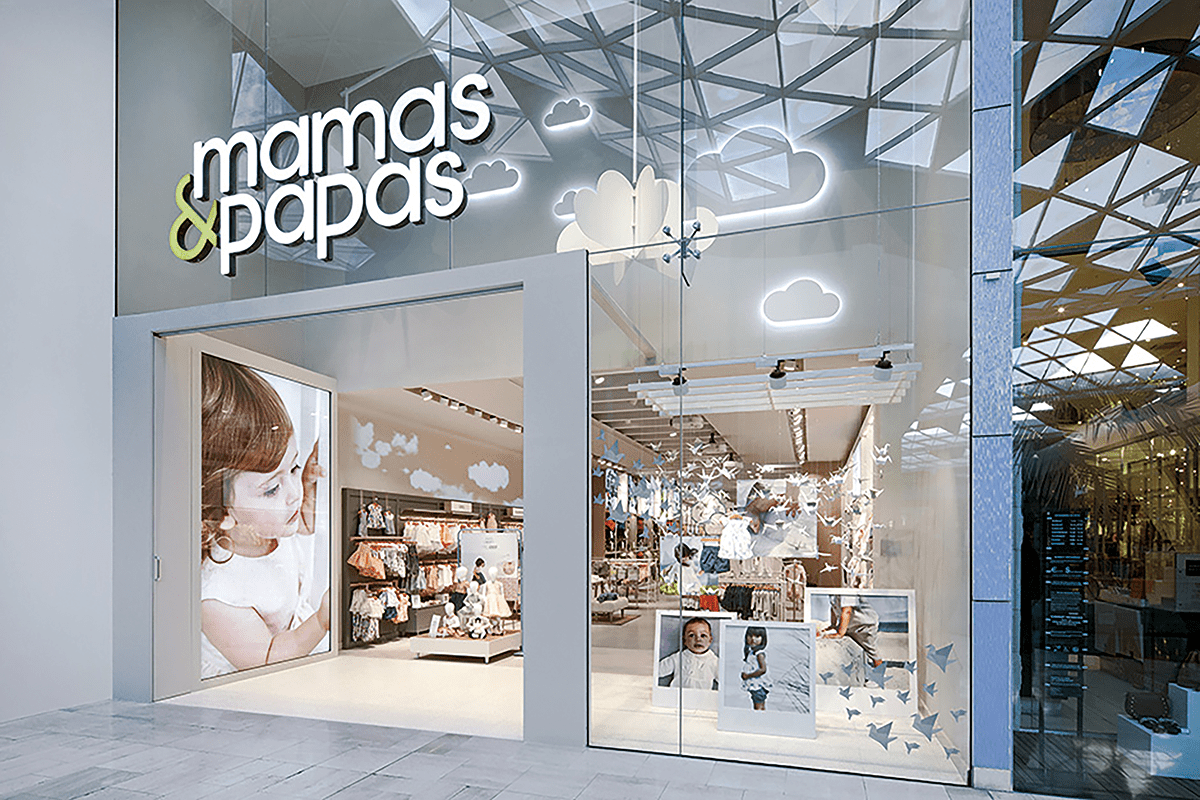

Mamas & Papas sells baby and nursery items to consumers in the UK and internationally. A customer’s order can consist of items of varying sizes such as a cot and some new-born clothing, a pushchair or simply a soft toy.

The customer may also not want their order dispatched immediately preferring a specific time slot before a baby’s due date. They also may want their order delivered on the day their order is placed, the next day, delivered to the room of their choice or utilise other services such as “build,” explains Chris Greenwood, CIO, Mamas & Papas.

Orders therefore could be fulfilled within 30 minutes of the order being placed or up to 6 months later. “We pride ourselves on getting everything right and to the customer at precisely the right time that they want it,” he says.

The Mamas & Papas operations team therefore need to be able to cope with differing sizes of their own goods, a multitude of carriers and branded goods which could be cross docked to ensure that they reach the customer at the right time.

Something that’s being manufactured could be ordered by Mamas & Papas to arrive into the warehouse a couple of weeks before it needs to be dispatched to the customer.

A warehouse in Huddersfield is responsible for UK orders and store replenishment with international warehouses in Hong Kong and near Los Angeles, operated by a 3PL, handling the retailers’ international operations. The retailer operates a wholesale business too.

Mamas & Papas operates a single stock pool and this is controlled by an in-house built Warehouse Management System (WMS) which allows the company to deal with stock as efficiently as possible. The decision to build the solution itself was based on the range of products and services which the company offers.

With anything from booties to wardrobes needing to be delivered at the same time, the retailer struggled to find a solution that matched the requirements of what it needed to offer. “Around 75% of our systems are developed in house because those are the areas in which we can be really efficient,” says Greenwood. Much of it is specific to the nursery business.

“We can bulk pick for our wholesale customers and be picking a smaller parcel for our retail customers at the same time,” he adds.

The retailer uses different carriers to deliver the various sized orders to customers in the UK and internationally. Hermes, for example, could be selected to deliver a small parcel, DPD for medium parcels, Yodel for large parcels and 2-man delivery from other carriers, Greenwood explains. As well as the size of the parcel, the criteria for choosing a specific carrier for an order also includes the items within it, the location of the customer, whether a 2-man delivery is required and any services which the customer has chosen.

It’s therefore important for the company to be able to manage the labelling and requirements of the different carriers to ensure easy transition between the warehouse and the carrier’s processes. Mamas & Papas also needs to be able to onboard new carriers easily and link customers’ delivery and service requirements chosen on the website with its operations and carrier capabilities.

The retailer worked with GFS on the development of its GFS Checkout solution having already implemented the GFS Selector carrier management solution. As Greenwood explains, somebody who is already dealing with all the carriers means that we could onboard other carriers very quickly. “Sometimes that’s necessary if we get a new customer who has very specific requirements and needs a specific carrier and a specific label,” he says.

The GFS Checkout system, which controls the delivery options shown to shoppers when they place an order on the website, integrates with the WMS so that the website knows whether products are in stock. If a product isn’t available for 6 weeks, for example, the option of next-day delivery won’t be shown to the customer.

It doesn’t select the actual carrier but the attributes of the type of carrier based on rules set by the retailer. The order is then passed to the WMS, is scheduled for dispatch and the label system decides on the number of parcels and labels which are required. These are printed out at the end of the picking process.

The Selector system also sends the information to the relevant carriers so that they are aware of parcels for collection. “It also means we don’t have to worry about trying to match manifest to goods being ordered. It takes away the need for us to do separate interfaces,” says Greenwood.

A website order containing multiple items is grouped into one parcel based on size of the largest item in the order and the location to which it is being sent. The retailer then slots the order into a time scale when the order can be delivered in its entirety and at a time convenient to the customer.

IN THE WAREHOUSE

Mamas & Papas worked with GFS in the early stages of the development of GFS Checkout so could influence what the technology did from a checkout point of view, so the company received exactly what it was expecting.

“It felt like a co-developed solution,” says Greenwood, “and it works to the exacting standards that we needed for our customers”. Implementation was “relatively painless” too but Mamas & Papas do a lot of testing of new systems. “There was almost no down time,” he adds.

The decision to go with an outside system rather than developing its own solution was down to the speed of implementation. Rather than having to develop solutions once the retailer started talking to a new carrier, 75% of the work that Mamas & Papas had to do had already been carried out by GFS, explains Greenwood.

“It makes life so much easier. Just setting configuration parameters is really the only thing we have to do development wise to onboard a new carrier,” he says. This can be carried out by the operations team.

Customer experience is important to Mamas & Papas as the accuracy and efficiency of its warehouse and fulfilment processes are driven by customer satisfaction. KPIs for the operations team include efficiency of getting goods through the warehouse and the speed of fulfilling orders.

The success of the GFS implementation, carriers and the retailer’s ability to ensure that things are in stock just in time are also measured along with the ability to move quickly, onboard other carriers as necessary and make changes and divert traffic as needs be. “GFS means we get things out of the door within a few minutes of the order being placed online and that is critical to us,” says Greenwood.

The next project for the IT team in linking operations with the customer-facing website is to increase the visibility of the delivery options earlier on in a customer’s journey so that they know how much they will be expected to pay for their delivery and when it can take place.

Another development for the hybrid-platformed website is development of the personal shop experience. These personal shops are bookable currently on the website but take place in store. They can take up to 2 hours with the potential customer being taken around the ranges offered by Mamas & Papas and helped with information about cots, pushchairs etc.

Greenwood explains that customers in this sector do a lot of showrooming with items viewed in store and then ordered online so that the retailer wants to expand the number of personal shops that can be performed in store, and possibly online too. “There are no promises to when this will take place as its early days yet,” he explains.