Currys Customer Repair Centre, Newark, is the largest of its kind in Europe, hosting 1,100 colleagues and handling three million products annually – including returns, repairs and recycling. InternetRetailing went behind the scenes to discover how the tech giant is educating its customers on the benefits of repairs; harnessing parts and knowledge from existing products; and taking control of recycling.

“ When we say we have the biggest repair centre in Europe or the largest operation, this is not just about the size – this is about the concentration of activity, knowledge, and capability in one place,” explains David Rosenberg, director of service operations at Currys.

A team of highly-skilled engineers offer a 24/7 service, only closing on Easter Sunday and Christmas Day. Currys’ Repair Live offering receives 600 video calls a week from consumers hoping to fix the issue via video call with an expert. Some 40% of these calls are software issues but all handled by engineers in a bid to limit the number of items coming back to the centre – in fact it prevents 25% of unnecessary returns with fixes achieved over the call.

The service, which has been running for three years, acts as a “live instruction manual” and aims to help and educate consumers.

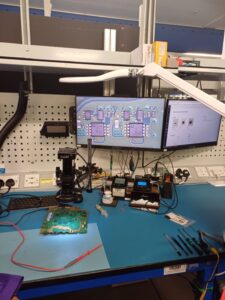

For items that require hardware repairs, the engineers are equipped with the knowledge and tools to deal with the most delicate parts – such as a microchip in the Playstation [pictured].

A critical part of the repair system at Currys is trying to reduce the number of new parts they require. To complete their repair offering 700,000 parts are needed, over 50% of these are now sourced internally by the Harvest team.

“In this economy we need to rebalance how much time we are gonna spend on the product; how much parts are we going to burn on the products; our engineers here in the UK are working on the most complicated machines; what do we want to do with the spares?,” notes Rosenberg.

When a part can’t be harvested from existing products, the team are harnessing advancements in material technology with 3D printers. They even want to establish a digital library of potential parts, that can be 3D printed in the future.

The centre is working to not only repair laptops, mobile, phones and game consoles, they are looking to better understand this technology and how to improve it. Thus, Currys has invited Samsung and LG to the centre to learn how to improve repairs, with both implementing the same way of approaching TV repairs at their own operations.

Initially the centre focused on phone, laptops, consoles (with white goods downstairs for weight and water reasons), Currys engineers are turning their attention to small household appliances such as airfryers, coffee machines, irons and printers.

Repaired products can then be sold on currys.co.uk refurbished section, its eBay branded store front or in the Manchester bricks-and-mortar store.

Each product comes with a QR code digital passport, and arrives in packaging which has its own IP as the retailer works to give customers a positive first impression of pre-loved products.

Recycling

For those products which cannot be the repaired, or items which come back into the retailer from its Cash for Trash initiative, the centre also has an expansive recycling operation.

The centre processes 50,000 tonnes of White Goods recycling each year. With the Currys’ drivers unboxing at a customer’s home and bringing the packaging back, this not only utilises the trailer on the return journey but also means 10,000 tonnes of cardboard is recycled responsibly.

Polystyrene is used for housing isolation – at a value of £1mn annually. While, Polythene then goes back into the Currys carrier bags – with 30% recycled material in each.

Additionally, Currys works with Reuse Network to help 10,000 low-income families access white goods they could not previously afford.

While all of this is very impressive, and on a substantial scale, the retailer thinks it can do more.

“How can we get critical raw materials from the products? Processes like bioleaching – a lot of these products, especially the older products you see come through the charities, the old circuit boards for example have so much more gold in them than the new ones,” notes Chris Brown, head of sustainable operations & compliance, Currys.

“A lot of that we send it to a recycler, which is the right thing to do because it makes sure the data’s removed. But there’s so much more I think we can do with that product ourselves. Getting those raw materials from products, especially the older ones, is a goal for me.”

The retailer also wants to increase the capacity of its circular operations, they have the space at Newark, the apprentice scheme to train new technicians, but are aware that they must continue to innovate. “We need to adapt to the next generation of new technology,” states Rosenberg.

Of course, advancements in technology will also help Currys adapt. It recently trialled new AI diagnostic tools for its repair platform. Rosenberg explains that if a customer has an issue with a washing machine, instead of trying to describe the problem to a call centre they can download the AI-powered tool and take a video of the product, noting what their fault is.

He says: “ We’re providing World class performance on the first visit because of this new AI solution that we deployed. It’s a game changer, and we are expanding it to return.”

The system creates a simpler journey for the customer, “there is no queue, no dependency to opening houses. Just talk to us, what’s your problem?”, he adds.

“There’s a huge amount of ambition. You could think of AI as an area which is creating a difference immediately. It’s like 3D printing. It’s great to have it. What you have to look at is how do you monetise this? How do you create a difference?”

This difference can already been seen throughout the centre, and the pride the team have in their operations. Damien Rogers, general manager of Customer Repair Centre, tells us that engineers stay with Currys for decades, and are actively looking for ways to improve technology in the long run.

Stay informed

Our editor carefully curates two newsletters a week filled with up-to-date news, analysis and research, click here to subscribe to the FREE newsletter sent straight to your inbox and why not follow us on LinkedIn to receive the latest updates on our research and analysis.